ENGINEERING CAPABILITIES

Custom Formulation

At the start of the development process, it all starts with the formulation. How is the vinyl film expected to perform and how can Presco custom formulate to the specifications?

Our unique dry blend compounding process allows for customization at every level of the formulation. We can utilize specialty resins such as high molecular weight resins, as well as, many types of plasticizers. Formulations that are heavy metal free, DEHP free and phthalate free are available. Specialty additives such as flame retardants, antimicrobials, dulling agents, aromatics, and UV stabilizers can be added based on specifications.

Presco’s PVC film can be formulated to meet very stringent color specifications. Infrared pigments can also be utilized for military colors. Our in-house lab extruder provides pantone color matching prior to large production runs. This allows our customer to see the film and approve the color without having to invest in a minimum order.

PHTHALATE FREE VINYL

Phthalates are commonly used chemicals to soften plastics, prevent nail polish from chipping, extend the life of fragrances and as additives in personal/health care items such as cosmetics and shampoos. Because Presco’s PVC film is formulated, compounded and extruded in our facility, Presco is able to offer a full line of custom phthalate free formulation options.

The following general purpose plasticizer options are currently available and can be used to develop phthalate free formulations:

- DOA

- DOTP

- TOTM

In addition, the following phthalate free plasticisers are under development and Presco is willing to investigate other options to meet market needs.

- DINCH

- Soft-N-Safe

- Natureflexx

- Citrates

- Succenic Acid

- Polymeric

In recent years, some phthalate esters have been alleged to cause negative health effects particularly hormone disruption, posing a reproductive health risk. These allegations are disputed by a wide range of manufacturers and industry organizations. In addition, the alleged negative effects stem from children ingesting the phthalate esters while chewing on plastic. Regulations are focused on plastics designed for the use in child applications and environments, a small portion of the vinyl market. Despite the uncertainty over the health threat of phthalate esters, their use is regulated in several specific applications.

UNITED STATES REGULATIONS:

The Consumer Product Safety Improvement Act (CPSIA), regulates phthalate esters as components of children’s toys and child care articles for children under the age of 12 that could be ‘placed in the mouth’. CPSIA permanently banned the following phthalates at levels greater than 0.1%.

- Di2-ethylhexyl phthalate (DEHP)

- Dibutyl phthalate (DBP)

- Butyl benzyl phthalate (BBP)

CPSIA has an interim ban on the use of the following phthalates at levels greater than 0.1% pending further review.

- Di-isononyl phthalate (DINP)

- Di-isodecyl phthalate (DIDP)

- Di-n-octyl phthalate (DNOP)

EUROPE REGULATIONS:

The European Union banned the following 6 phthalate esters in toys and children’s products that might be placed in the mouth, at levels greater than 0.1%. The EU extended the limitation to the use of these phthalates in general food contact applications and medical devices.

- Di-2-ethylhexyl phthalate (DEHP)

- Dibutyl phthalate (DBP)

- Butyl benzyl phthalate (BBP)

- Di-isononyl phthalate (DINP)

- Di-isodecyl phthalate (DIDP)

- Di-n-octyl phthalate (DNOP)

Other phthalates were listed by the EU as Substances of Very High Concern (SVHC) under the REACH regulations.

- Di-butyl phthalate (DBP)

- Di-2-ethylhexyl phthalate (DEHP, DOP)

- Butyl benzyl phthalate (BBP)

For more information, visit:

www.pvc.org

www.phthalates.org

www.phthalates.com

www.plasticsindustry.org

www.vinylinstitute.org

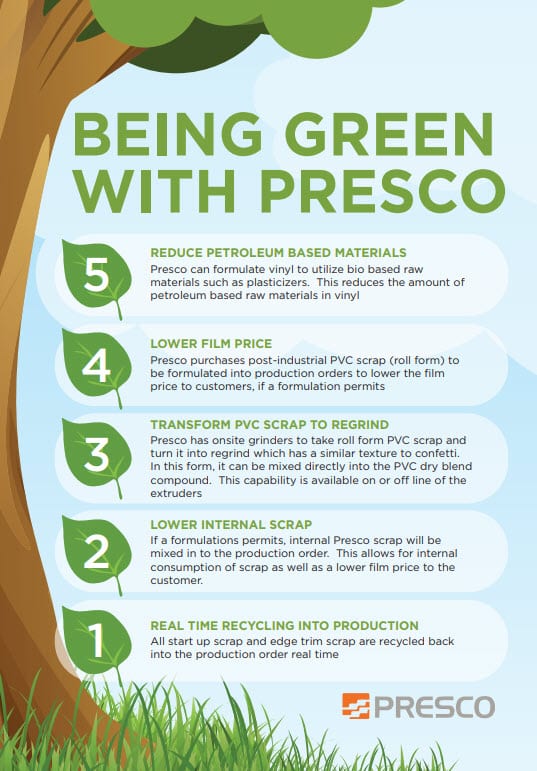

BEING GREEN, THE VINYL WAY

For many years, Presco has placed great importance on meeting our goal of consuming 100% of the waste our manufacturing process generates. That goal has not only been met, but exceeded. We not only consume all of the waste Presco generates, we also buy post-industrial vinyl film waste from other manufacturers who are unable to consume the waste themselves.

How? You ask…..

The waste is processed in house and turned into a regrind, similar to confetti. The regrind is segregated by color and stored in our warehouse. When a color and formulation opportunity is seen on the production schedule, the regrind is added in batches to the formulation during the compounding process. Some formulations, such as medical, do not allow for any outside regrind. All of the formulations are adjusted to account for the added regrind.